In the manufacturing sector, where innovation and precision are pivotal to success, 3D product modelling has emerged as a transformative force. As a manufacturer, you’re constantly looking to enhance product design, streamline development, and captivate your customers. 3D product modelling is a powerful tool to help you achieve these objectives.

This article delves into the numerous benefits of 3D product modelling for manufacturers. From improved product visualisation to more efficient design processes and enhanced marketing strategies, we’ll explore why integrating this technology into your workflow is beneficial and increasingly essential.

Enhanced product visualisation

One of the most significant advantages of 3D product modelling is the ability to visualise a product in high detail before it exists physically.

More than a picture: An immersive experience

With 3D models, you can provide an immersive experience that a simple photograph or 2D drawing cannot match. Potential customers can view your product from every angle, understand the scale, and appreciate the finer design elements, which can be pivotal in their decision-making process.

Customisation and variations

The flexibility of 3D modelling allows you to showcase various product variations quickly and cost-effectively. Whether different color schemes, materials, or design tweaks, manufacturers can present various options to their customers without needing multiple physical prototypes.

Streamlining the design and development process

3D product modelling is beneficial for visualisation and streamlines the entire design and development process.

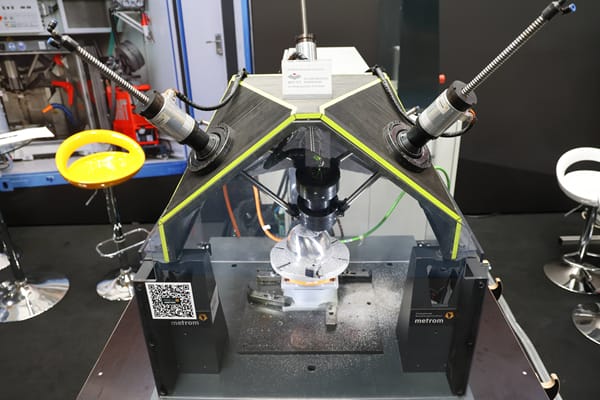

Rapid prototyping and testing

With 3D product modelling, manufacturers can swiftly create and refine prototypes. It enables you to test functionality, aesthetics, and ergonomics virtually. Identifying and addressing design issues early can save time and resources that would otherwise be spent on multiple physical prototypes.

Precision and accuracy

3D modelling software allows for precise measurements and tight tolerances, which are critical in manufacturing. This level of accuracy ensures that parts fit together correctly the first time, reducing the need for costly reworks.

Cost-effectiveness

Reducing costs while maintaining quality is a significant challenge for manufacturers. 3D product modelling can be a cost-effective solution.

Less material waste

Since 3D product modelling allows for extensive testing and refinement in a virtual environment, physical materials are only needed once the design is near perfect. This results in less waste and more savings.

Time and resource savings

3D modelling can dramatically reduce the time needed to bring a product to market. With a more efficient design process, manufacturers can allocate resources to other areas, such as marketing or research and development.

Marketing and sales advantages

3D product modelling also offers substantial benefits in terms of marketing and sales.

High-quality product renderings for marketing materials

Using 3D models, you can create photorealistic renderings for your marketing materials. These renderings can be more appealing than traditional photography and can be produced without the logistical challenges of a photoshoot.

Interactive product demos

3D models can create interactive demos that engage customers and provide them with a hands-on experience. This interactivity can lead to a better understanding of the product and its features, significantly influencing purchasing decisions.

Overcoming geographical limitations

3D product modelling helps manufacturers overcome geographical limitations in an increasingly global market.

Sharing designs with remote teams and partners

3D models can be shared electronically with teams worldwide, facilitating collaboration and communication. This is particularly beneficial for manufacturers with multiple locations or those who work with international clients.

Online product showcases

Manufacturers can showcase their products online using 3D models, reaching a wider audience without physical showrooms or trade shows.

Future-proofing your manufacturing process

Staying ahead of the curve is crucial in the rapidly evolving manufacturing industry.

Compatibility with emerging technologies

3D product modelling is compatible with other cutting-edge technologies, such as augmented reality (AR) and virtual reality (VR). These technologies can provide even more immersive customer experiences and are becoming increasingly important in product development and marketing.

Scalability for growth

As your business grows, 3D product modelling offers scalability. You can easily update models, create new variations, and expand your product offerings without a proportional cost increase.

Success stories of 3D product modelling for manufacturers

To illustrate the impact of 3D product modelling, let’s look at a few examples.

Furniture Industry

3D product modeling enhances the furniture industry by enabling manufacturers to create accurate and detailed digital prototypes, streamlining the design and production process.

Automotive industry

In the automotive industry, manufacturers use 3D models to design parts and create interactive showrooms for customers to explore different vehicle options.

Consumer electronics

Consumer electronics companies often use 3D models to design intricate components, ensuring that everything fits together perfectly and that products are functional and aesthetically pleasing.

Partnering with 3D modelling specialists

For many manufacturers, the most efficient way to harness the power of 3D product modelling is to partner with specialists. These experts bring a wealth of knowledge and experience in product visualisation, ensuring that your 3D models are of the highest quality. They can also offer insights into emerging technologies and trends within the industry, keeping your business at the forefront of innovation.

The competitive edge of 3D product modelling

In conclusion, 3D product modelling offers a plethora of benefits for manufacturers. From enhanced product visualisation and streamlined design processes to cost savings and marketing advantages, it’s a technology that can give manufacturers a competitive edge.

By adopting 3D product modelling, you can improve collaboration, reduce time-to-market, and provide customers with a superior understanding of your products. As the manufacturing landscape continues to evolve, integrating 3D product modelling into your workflow is not just a strategic move—it’s an essential one for future success.

Leave a Comment