Mass production is a fundamental of many industries in the modern world as it makes it possible to produce large quantities of plastics and metal parts. In consumer electronics and automotive parts, where customers’ growing needs are being fulfilled by high-volume products, mass production cannot be overlooked.

Understanding mass production

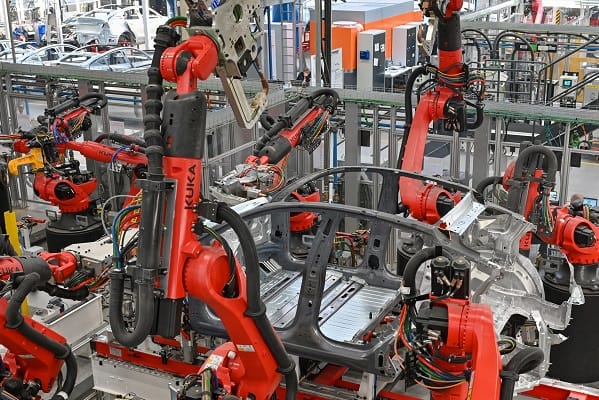

The term refers to the production of a large number of standardized products within a relatively short time; the procedures involved include the assembling line and mechanical equipment. Its primary objective is the production of a high number of units with steady quality standards and reasonable prices. This is particularly important if the demand for the parts is high such as in automotive, aerospace, electronics or the consumer industries.

Techniques in mass production

Injection molding

This is a common way to make lots of plastic parts. In this method hot plastic is poured into a shaped container, where it hardens into the needed form. It is highly efficient because it allows for high volume production while consuming very little time and material.

Stamping and forging for metals

Among the various methods of manufacturing the metal parts stamping and forging are among the most widely used. Stamping involves the use of die to sow a metal sheet in a preferred shape while in forging, metal is shaped under pressure by the application of heat. Both of them offers accuracy and consistency that is desirable for mass production.

CNC machining

CNC machining can be employed on both the plastic and metallic ones and is a multipurpose tool that can be applied to different industries. It entails employing automatic tools to get rid of materials from work pieces according to controlled instructions. CNC machining offers great accuracy thereby suitable for high volume production complicated intricate designs are required.

Advantages of mass production

Economies of scale

Mass production helps manufacturers achieve economies of scale by spreading fixed costs over many units hence reducing cost per unit. As a result, products become more affordable because the cost efficiency is passed onto consumers.

Consistency and quality

Mass production ensures that quality remains the same for all units using automated processes and standardized procedures. In an industry where precision and safety are important, this reliability is essential.

Speed and efficiency

High volume production means less manufacturing time hence enabling companies to meet their deadlines on time and prompt market demands fulfillment.

The future of mass production

Technological advancements continue to shape mass production. Little by little additive manufacturing or 3D printing as this technology is most popularly known is gradually becoming an option for manufacturing metal and plastic parts. This technique allows designs to be created quickly and in small quantities thereby making them much more flexible, meaning the amount of waste material produced is minimized.

Also, integration of Industry 4.0 principles such as Internet of Things (IoT) and artificial intelligence (AI) have transformed high volume production processes. The smart factories with real-time monitoring and predictive maintenance enhance efficient use of resources by minimizing downtime while maximizing overall productivity.

Leave a Comment